Quality is to pay attention to every detail

LK Mould Industry Co., Ltd is very strict according to DME/HSACO/LKM standard and customer require for plastic mould quality control, and offer Weekly Report for on time deliver.

-

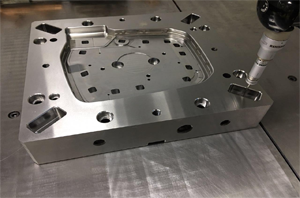

Inspection machine and tools:

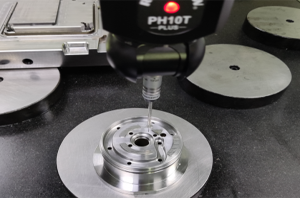

· CMM

· Optical Measuring Projector

· Hardness gauge

· Vernier caliper, micrometer, thick/thin plug gauge, screw gauge

· Toolmaker Microscope, height master, surface Plate

-

Inspection content:

· Customer’s Mould Specification Sheet Check

· Design Optimize control

· Mould Steel Hardness Inspection

· Mould Electrodes Inspection

· Mould Core and Cavity Steel Dimension Inspection

-

We take on your manufacturing risks

· Mould Pre-Assembly Inspection

· Mould Trial Report and Samples Inspection

· Mould Pre-Shipment Final Inspection

· Mould Package Inspection

Quality Control We perform strict QC measures following ISO 9001,TS16949 standards.

The QC system includes QC, IQC, IPQC and QA. The experienced QC team is equipped with

advanced machinery.

We also have strict supplier apporval procedure to ensure all the materials used in our products

satisfy customers requirements. Besides, the R&D department provides technical support

throughout the entire production process.

All sampling and testing used for acceptance of material is required to be conducted by a

Qualified Technician.

Quality control chart should be filled daily by related QC and confirmed by supervisor.The

equipment furnished for testing is required to be properly calibrated and maintained within the

calibration limits described in the applicable test method.

LK Mould Industry takes the quality as our first task. We have consummated quality control system, ISO and environment management, it mainly includes the 4 sections,

1.Technical Measurement,

A The measuring tools management, make sure all measurement instruments and equipments are properly calibrated and maintained.

B Products measurements.

Making incoming inspection working instruction, for example, to check the steel, the mould base, the standard components, the ejectors etc.

Mould inspection and checking before delivery, to make sure to meet the requirements, and avoid the potential issues.

Processing inspection, including, electrodes measurement, machining tools measurement, hardness and surface checking after the heat treatment