Commonly materials used for die-casting products as following:

Zinc alloy, aluminum alloy and magnesium alloy. Aluminum alloy products are often used in

the automotive industry, motorcycle industry, aerospace etc.

LK Industry continues to provide customers with better die-casting products and services.

Now we have 8 cold chamber horizontal die casting machines ranging from 100 tons to 800

tons. Using the latest die-casting manufacturing technology to supply high-quality molten

alloy for die-casting production.

At the same time, LK is equipped with mold processing equipment, which can manufacture

high-precision die-casting molds according to customer requirements, and produce various

specifications of precision aluminum alloy die-casting products for customers. The product

size is precisely measured by a CMM, and equipped with a CNC machining center and aCNC lathe to precisely process the castings according to customer requirements.

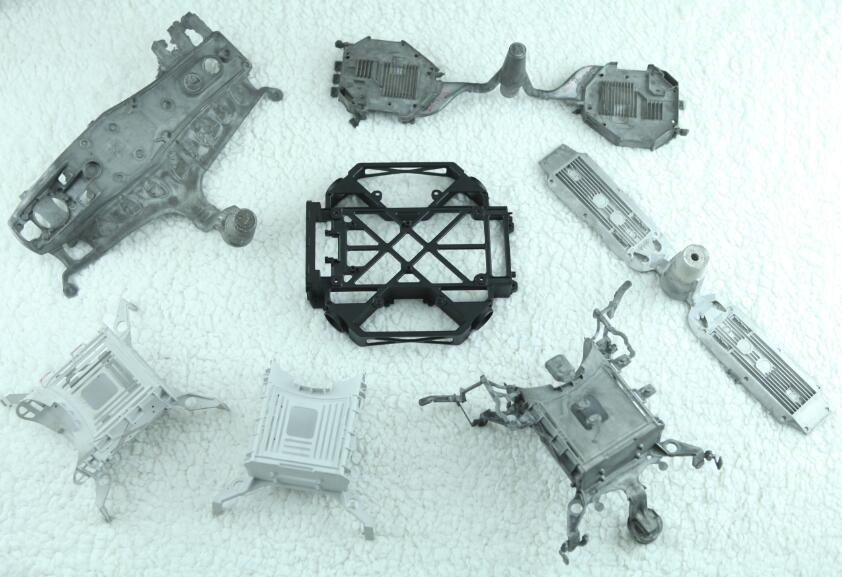

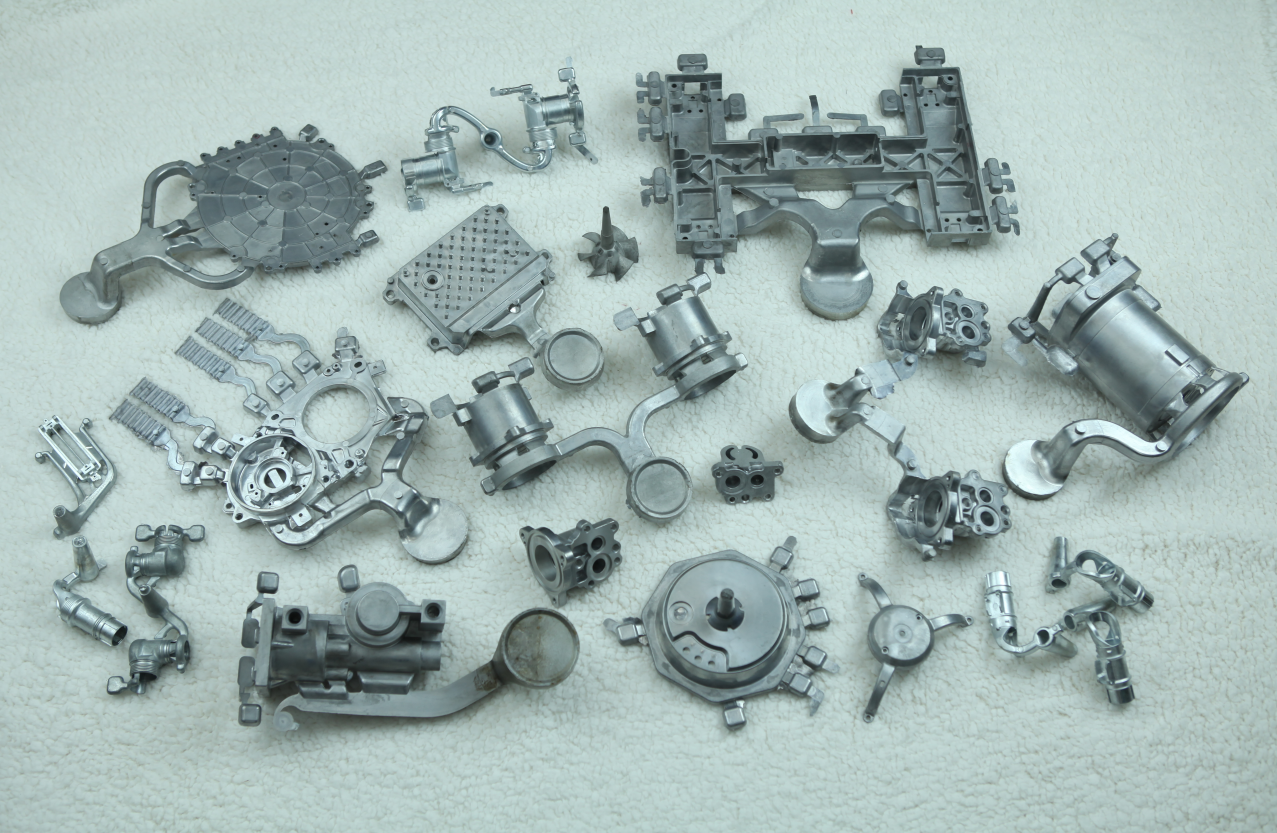

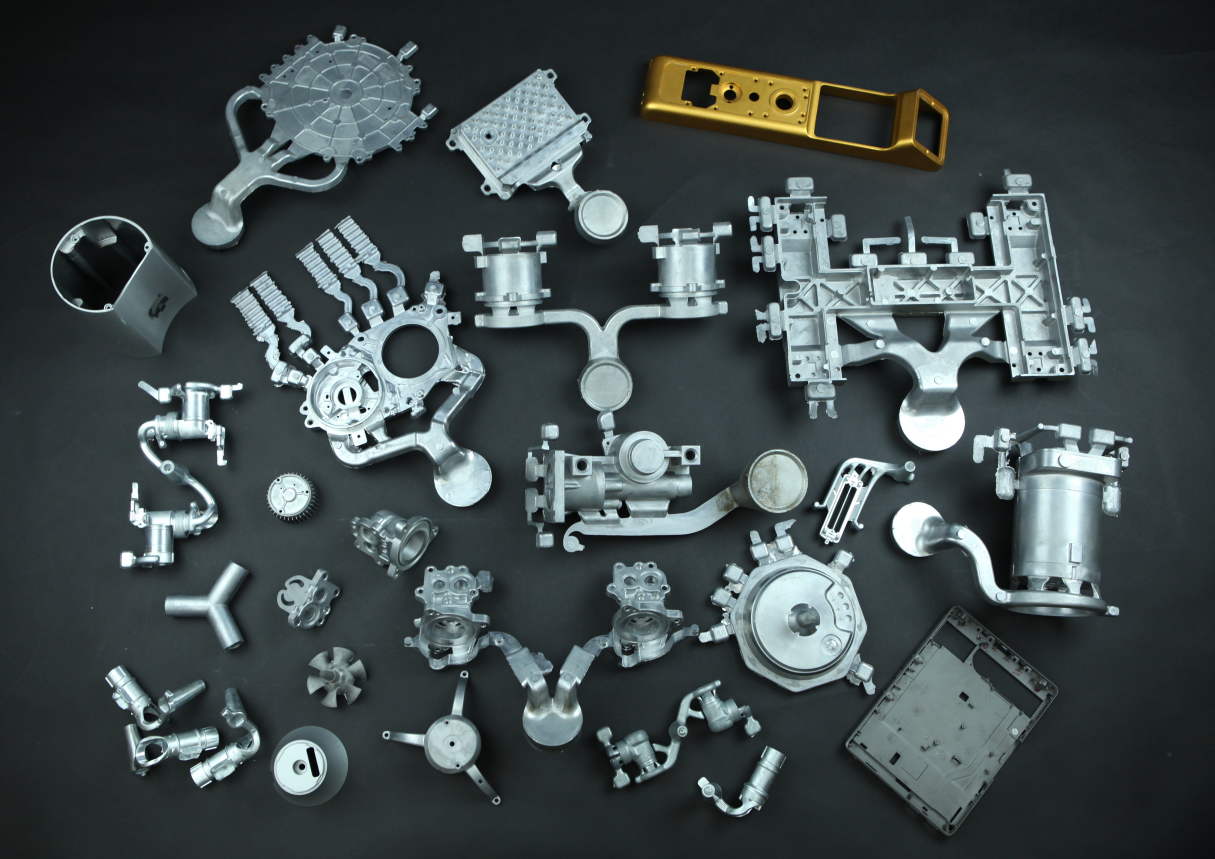

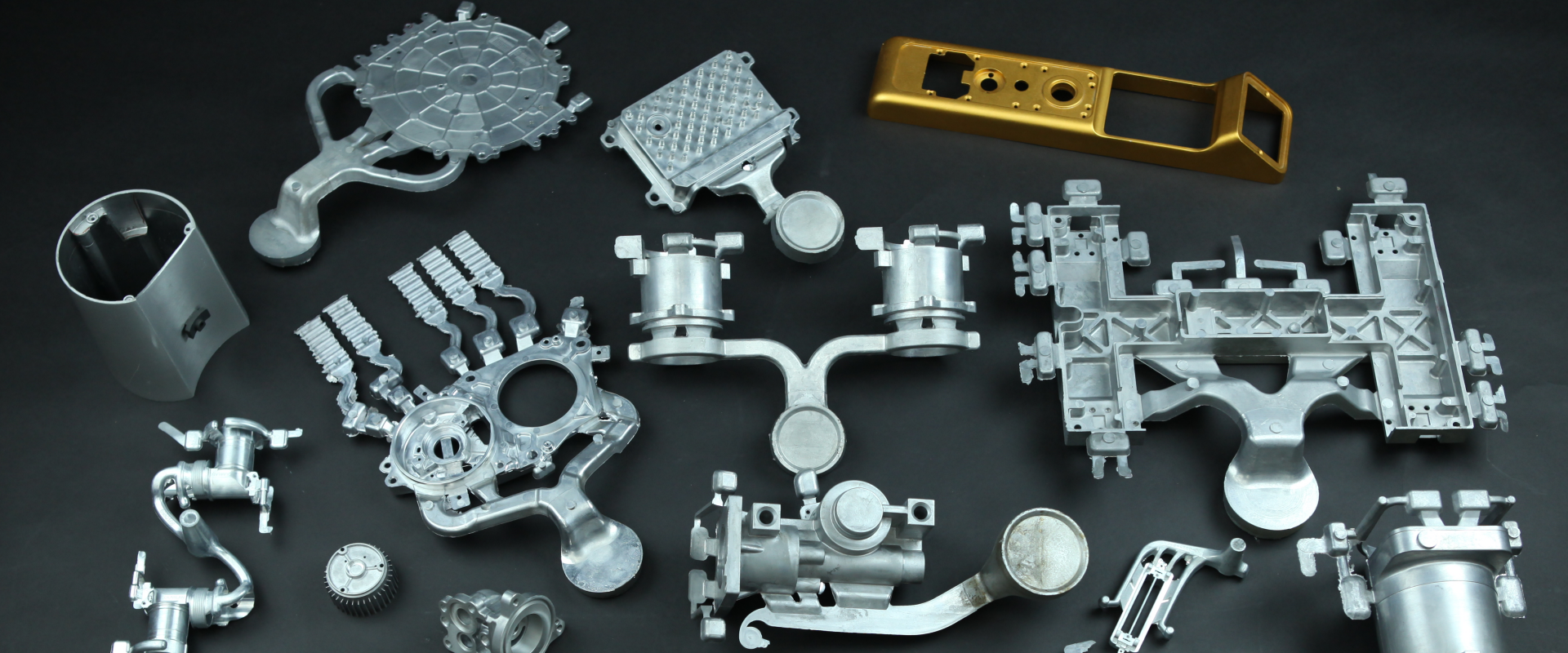

Below cases for your reference

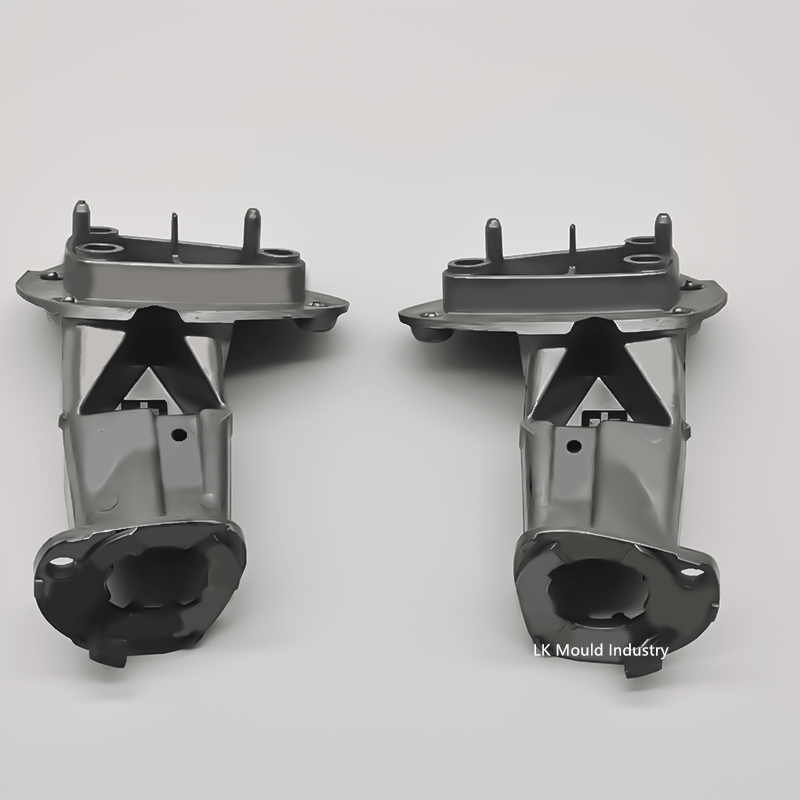

Rearview Mirror Aluminum Bracket

Product weight: 337 g

Casting material: Aluminum alloy (ADC12)

Product size: 156 x 115 x 87 mm

Die casting machine tonnage: 360T-400 T

Mold cavity: 1 x 2

Mold dimention: 665 x 723 x 626 mm

Mold weight: 1650 KG

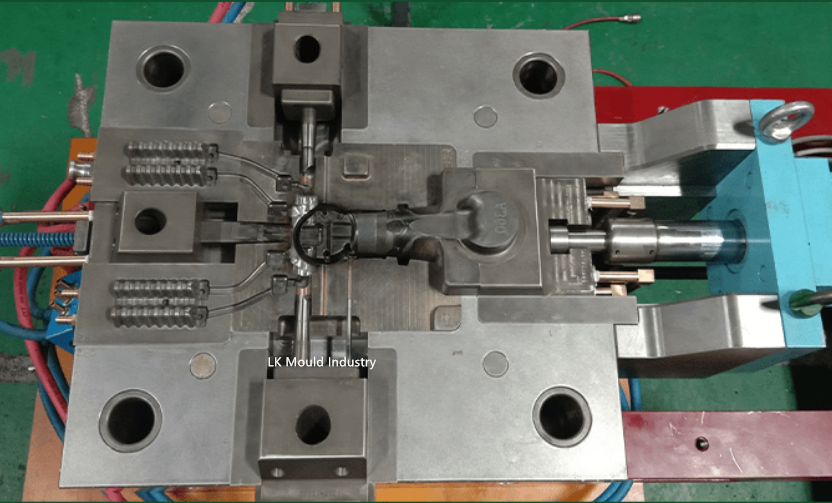

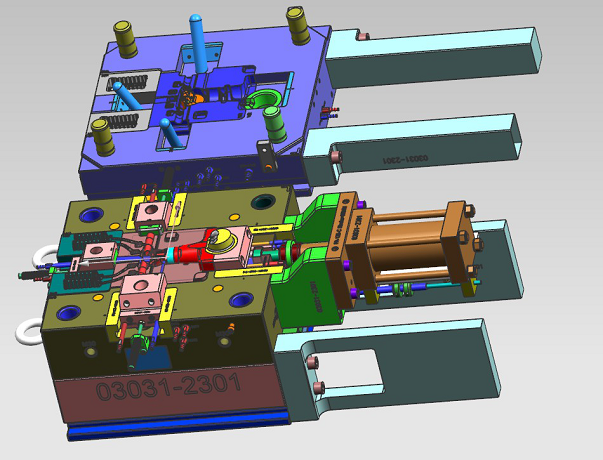

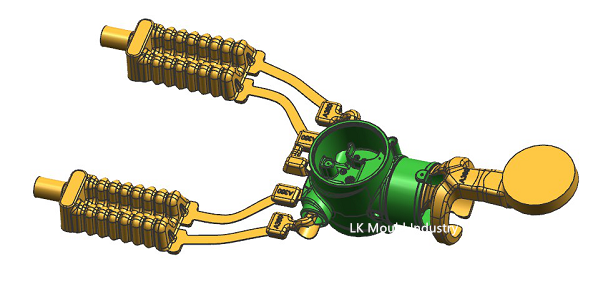

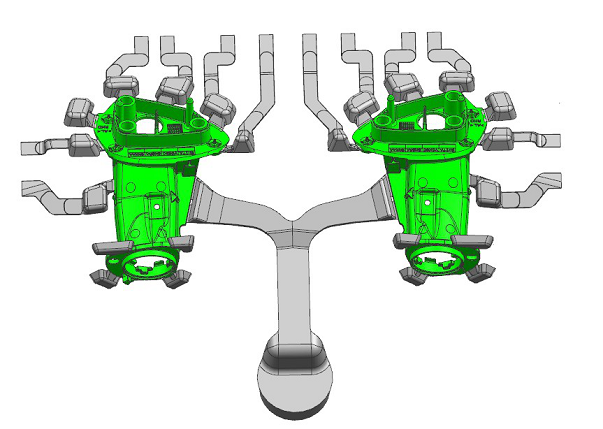

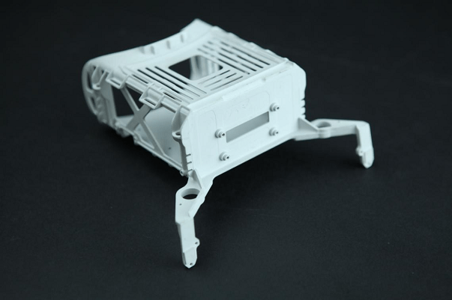

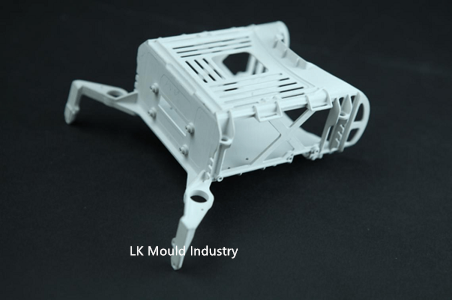

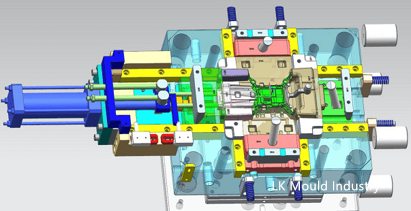

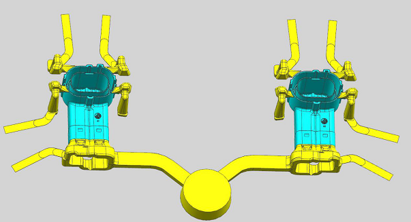

UAV battery bracket magnesium die casting mould

Product name: UAV battery bracket

Product weight: 54 g

Casting material: Magnesium alloy

Product size: 139.7 x 137.1 x 76.3 mm

Die casting machine tonnage: 280 T

Mold cavity: 1 x 1

Mold dimention:

500 x 600 x 456 mm

Mold weight: 1045 KG

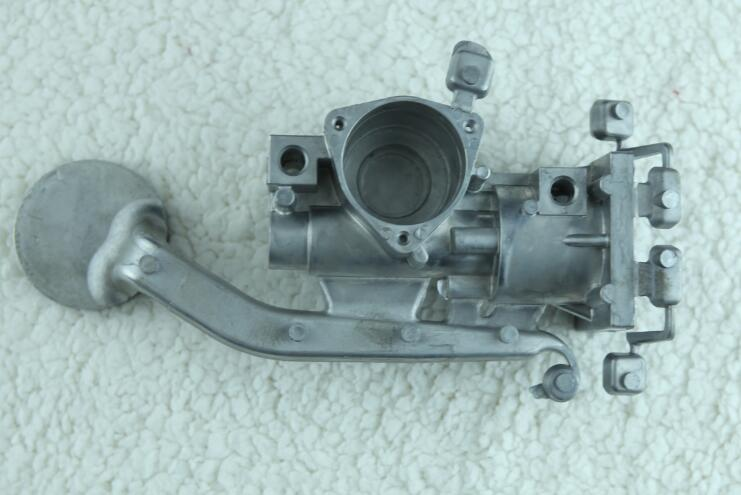

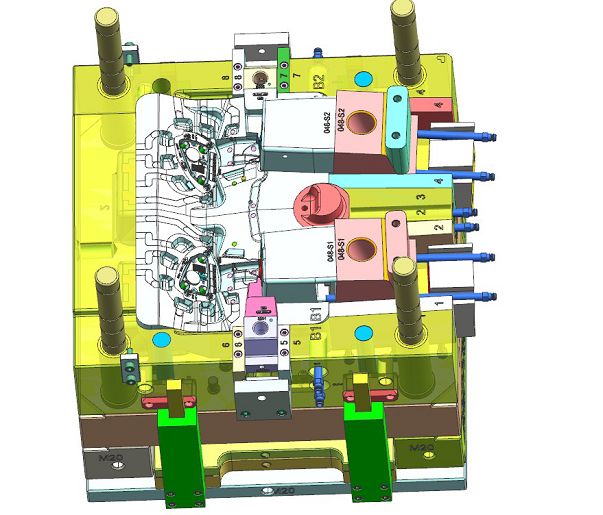

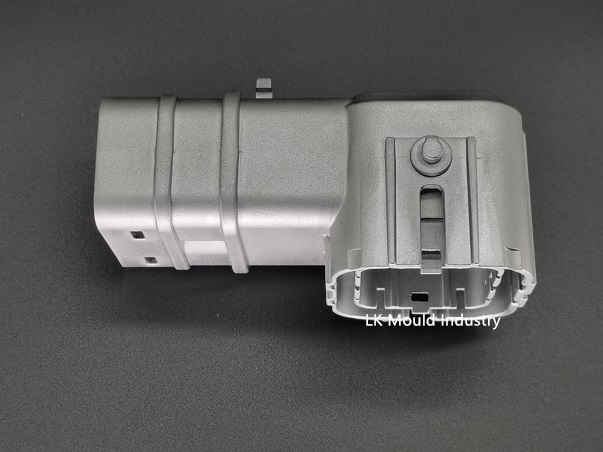

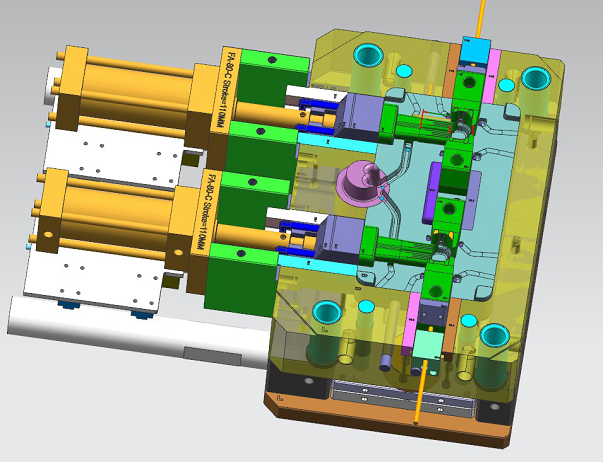

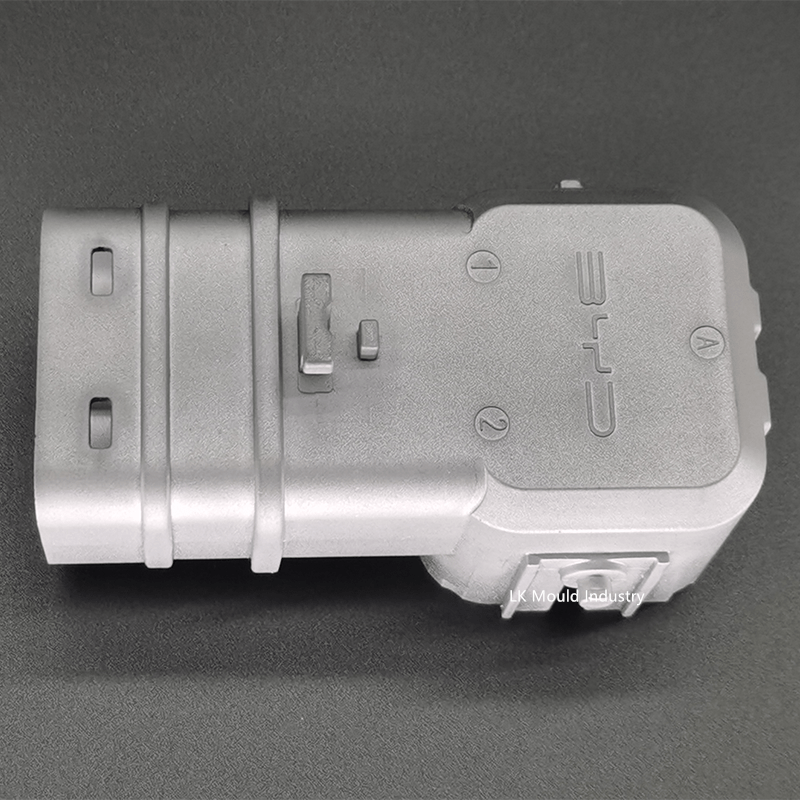

Die casting part for BYD new energy(electric) vehicles

Product weight: 128 g

Casting material: Aluminum alloy (ADC12)

Product size: 96.4 x 77.7 x 52.5 mm

Die casting machine tonnage: 400 T

Mold cavity: 1 x 2

Mold dimention: 455 x 700 x 405 mm

Mold weight: 1450 KG

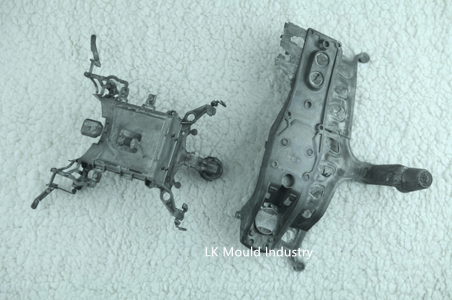

Small motor housing die casting mold

Material: Aluminum Alloy (A360)