Our Molding Making Capabilities

From prototoype to production molding, LK Industry custom molding service is ideal for the manufacturing of competitive pricing, high-quality molded parts in a fast lead time. Strong manufacturing facilities with powerful, precise machines ensure the same mold tool for creating consistent parts. Better yet, we provide free expert consultation on each injection molding order, including mold design advice, materials&surface finishes selection for your end-use applications, and shipping methods.

Our Mold Manufacturing Processes

See how we process your orders, from quotation to tooling, as our machines and efficient team ensure you receive your molds and parts within the scheduled lead time.

-

Request Instant Quote

Request your quote from our instant quote platform and our dedicated engineers will provide a response within 24 hours, ensuring the process goes on smoothly.

-

DFM Report

We also send an accompanying feasibility report containing suggestions for improvements to your design. This would make it easier to fulfill your production demands and increase the possibility of producing functional molds.

-

Mold Flow Analysis

We use computational software to predict how molten material will move in the produced mold. This helps us to offer even better suggestions regarding the mold design.

-

Mold Tooling Production

At this stage, we get to mold production using your desired material and manufacturing method. This ensures that we produce results suitable for your needed application.

-

T1 Sample Inspection

We deliver a sample of the produced parts so you can have a hands-on feel of the quality. This will help get any feedback that can finally be incorporated into the batch production phase.

-

Low Volume Production

After getting your input from the produced samples, we start the batch production phase. Here, we use our high-precision machines to ensure consistent quality and speedy production.

-

Strict Inspection

For quality control and assurance, we ensure all our manufacturing processes follow international tolerance standards.

-

Delivery

We partner with trustworthy logistics companies to deliver the parts to you in excellent condition and within the scheduled lead time.

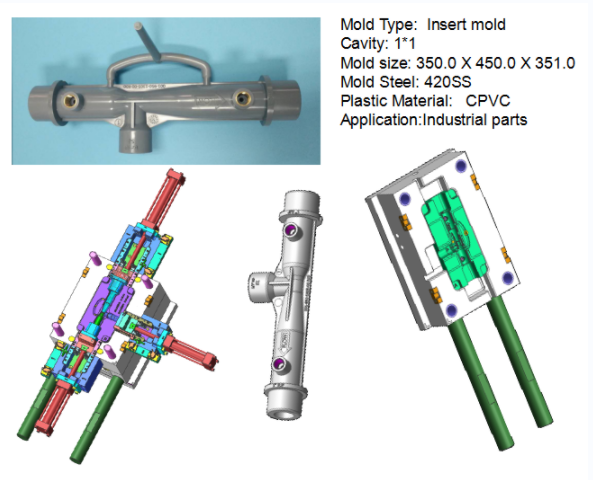

Mold Manufacturing

Follow the Process of Manufacturing from Design to Product.

Mold Design

LK Industry has 12 experienced engineers, who worked in this field more than 10 years. We always work with our customers in early stage to find risks and do co-work engineer before data frozen.

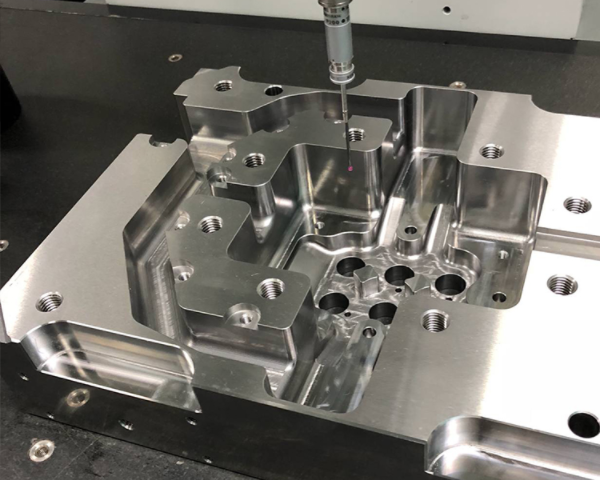

Mold Making

Applying the most sophisticated CNC machines and water jet cutters, Vorlane makes high precision mold with tight tolerance within ±0.01 mm, so that the designed housing can be perfectly molded.

Casting

This process involves injecting molten metal (usually aluminum) into a mold cavity to make the housing for the parts. We ensure the pressure of injection as well as the time spent in the mold, is controlled. This helps prevent cracking or any other physical deformation of the cast.

Injection Molding

We always use raw plastic resin (instead of cycle resin) to ensure we get the best plastic performance . Using Haitian injection molding machines, LK made the injection molding procedure reliable and precise.

LK Industry Made Facts

LK-Industry delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

- 4,500m² Specialized Plant Area

- 5 Production Lines

- 100~150 Mold Made Every Year

- 16+ Trusted Brands

CNC Workshop

EDM Workshop

Mold Fitting Area

Polish workshop

Mold Spotting Machine

CMM Inspection

Injection molding workshop

Die-cast molding workshop